Vacuum Metalising

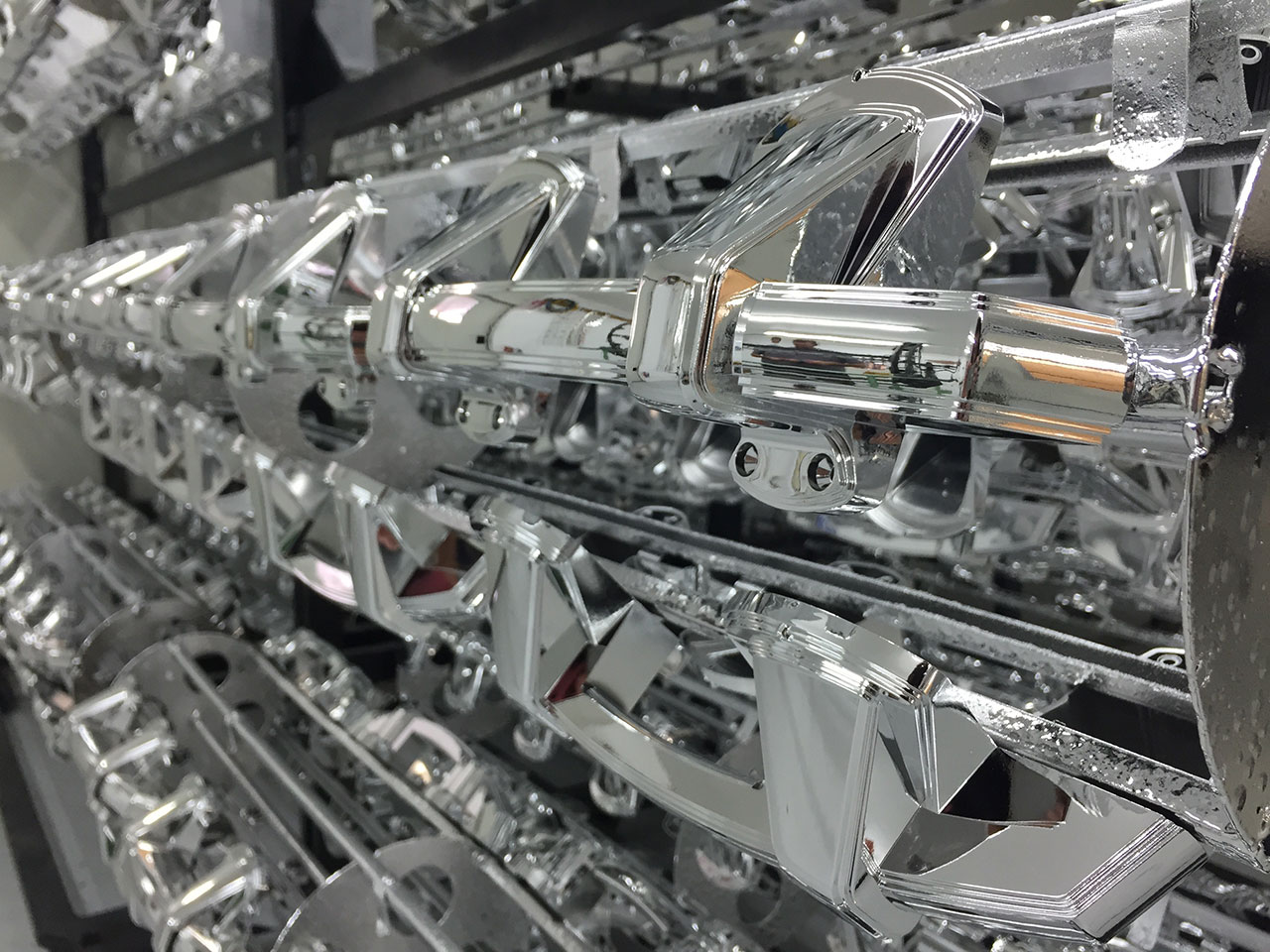

Achieve a chrome-like coating and apply a custom decorative finish to plastic products, toys etc

Do you have a plastic part that you want to apply a decorative finish to?

It is not that easy to nickel plate or achieve a chrome reflective finish on plastic. Vacuum Metalising is a process widely used to make, cosmetic closures, toys, light reflectors and automotive trim shine like a nickel or chrome reflective finish. With our vacuum metalising and painting processes we can apply a wide variety of decorative finishes to a wide range of plastic shapes, sizes and materials.

Vacuum Metalising Process

The vacuum metalising process is where aluminum is evaporated under vacuum to create an aluminium vapour cloud, when the vapour comes in contact with the parts, it condenses on the part and bonds to anything in its line of sight to form a uniform layer, which achieves the nickel/chrome reflective finish. After the metalising takes place there is a protective topcoat applied. A tinted topcoat is applied to create a wide range of metallic finishes including nickel, chrome, silver, semi satin, gold, bronze, copper and gunmetal.

There are many different applications for Vacuum Metalising and painting on plastic including light reflectors, automotive accessories, cosmetic closures, display items, gaming machines, helmets, art projects, automotive interior trim, toys, models, novelty items, anything requiring a decorative reflective finish

If you want the look of custom chrome on anything plastic or metal then contact Lucentt to see if we can help.